Best AC in India should have the best compressor and we need to understand different types of compressor. Every component inside an AC has a specific role in treating the refrigerant that is the main element of the complete system. One among them is a compressor. It has the task to compress the gas and increase its temperature, so the heated air goes to the condenser, and the cooling process initiated.

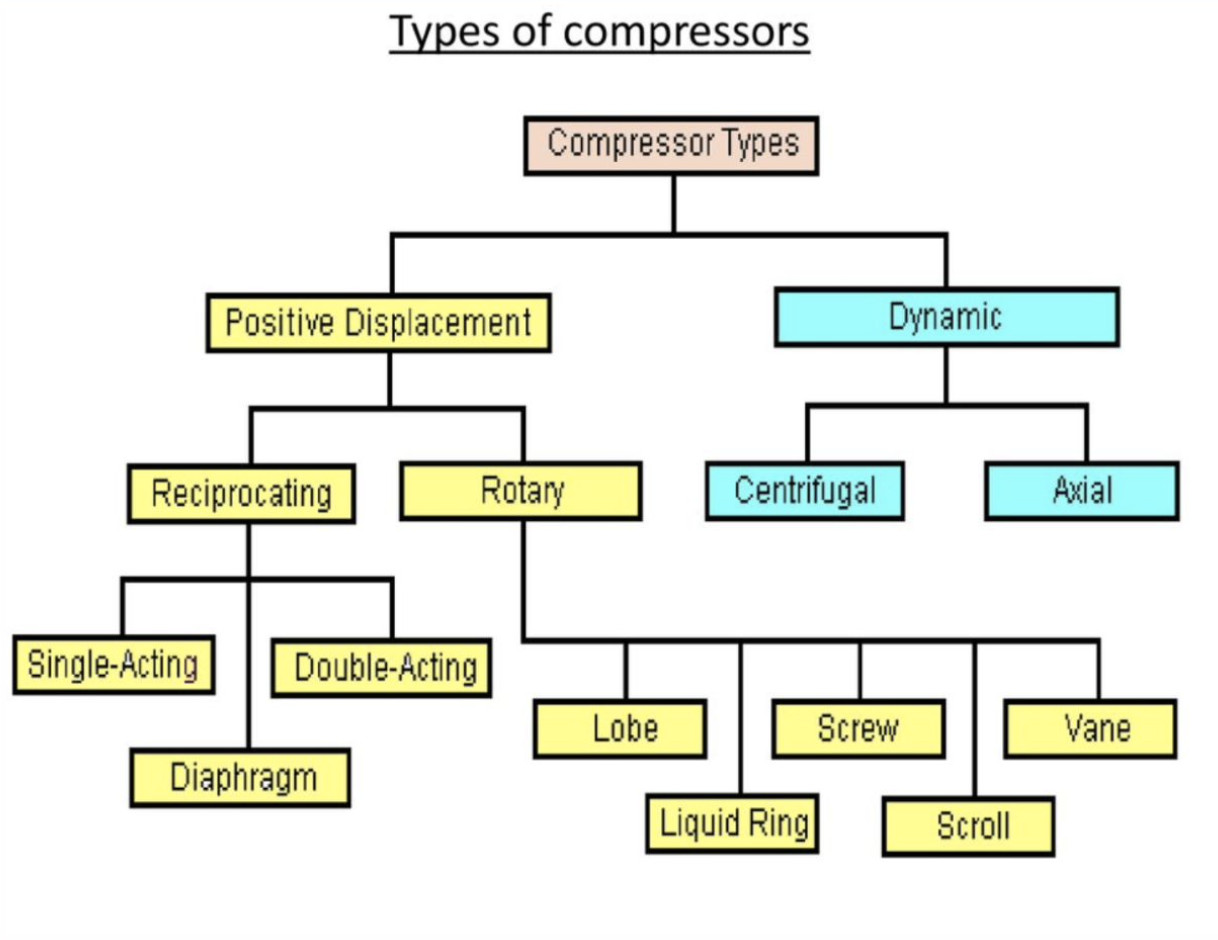

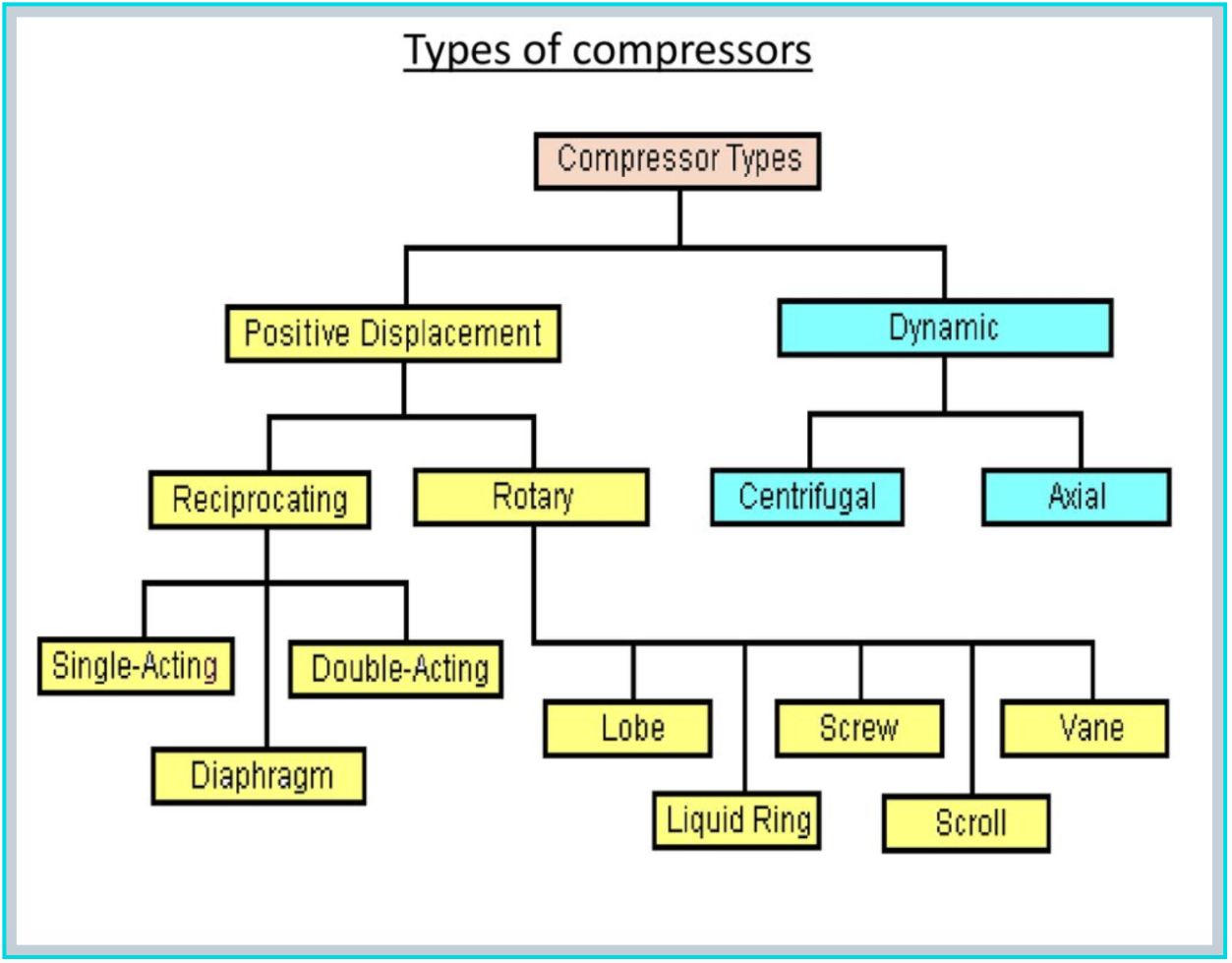

Do you know the truth that there are different types of compressors used in ACs? They all are having the same purpose but only differ in the ways of their working, and they come with their pros and cons.

Compressor Types

a) Rotary AC Compressor

It is a small-sized compressor that is usually used to avoid the noise and runs very quiet. The AC includes a shaft with many attached blades to it that rotates within a graduated cylinder.

Hence, the refrigerant will be pushed through the cylinder and simultaneously compressing it. It is common in central AC systems that are mostly used in larger homes or commercial places. The moving parts are likely to fail in less frequent use.

b) Scroll AC Compressor

In this type of compressor, there lies a scroll or fixed coil. It is present right at the center and surrounded by another coil that rotates over it.

In this procedure, the refrigerant is pushed towards the center by the second scroll, and hence compression occurs. They are common in ACs because there is no moving mechanism there that enhances its reliability.

c) Centrifugal AC Compressor

Here, the main principle is to use the centrifugal force. It includes attracting the refrigerant gas and make it spin at a fast pace using an impeller that further compresses it.

They are also known as radical compressors and are common on large AC systems. The manufacturing and relative costs are lesser. They are non-oscillating, energy-efficient, and give higher constant airflow against a reciprocating compressor.

d) Screw AC Compressor

Another kind of compressor commonly used in large buildings to maintain the temperature of a large amount of area. A screw compressor has much efficiency and is more reliable.

It consists of two big helical rotors that are responsible for passing the air from one end to another. As per the movement of the refrigerant gas inside the compressor, space decreases, and compression occurs.

They have more cooling capacity but lacks in power. It is smaller in size and energy-efficient that makes it well fitted inside smaller central or window AC units. It demands regular maintenance because an inefficient fan or dirty coils can imbalance the condensing unit.

The overheating may result in the shutting down of the AC. A machine comprising these compressors are generally of highly-priced. But it can save much of your power consumption in the future.

e) Reciprocating AC Compressor

It is a highly typical compressor used in air conditioners. A piston moves horizontally up and down inside the cylinder. It is responsible for compressing the air inside the same.

A vacuum effect is created inside the cylinder. It sucks the refrigerant and happens when the piston travels downwards. On reverse movement of the piston, i.e., upwards, the gas compresses and further goes to the condenser.

It is known to offer efficient results and consists of a maximum of eight cylinders inside the compressor. They are having limited cooling capabilities and mostly used in window based or smaller central AC systems.

On the other side, these compressors are durable. It is because of limited parts and can be repaired and replaced as compared to many modern compressors. These make noise during the operation.

What are the Qualities of a Good Compressor?

A compressor has to be decided by looking into the following features inside an AC system;

– The refrigerant flows under high temperature and pressure in the process. So there must be a safety device to handle such during compression.

– The need for using less power and offering cooling unit value.

– To manage the full and partial load of noise levels and vibration that goes at different altitudes and over a specific level.

– To make the movements of rotation smaller possible.

– The mechanism should be cost-effective.

– To lessen the partial load efficiency.

– To manage changes in the large load and continuous control of the capacity to match up with the work regime.

– In order to make a balance of safety under different work environments.

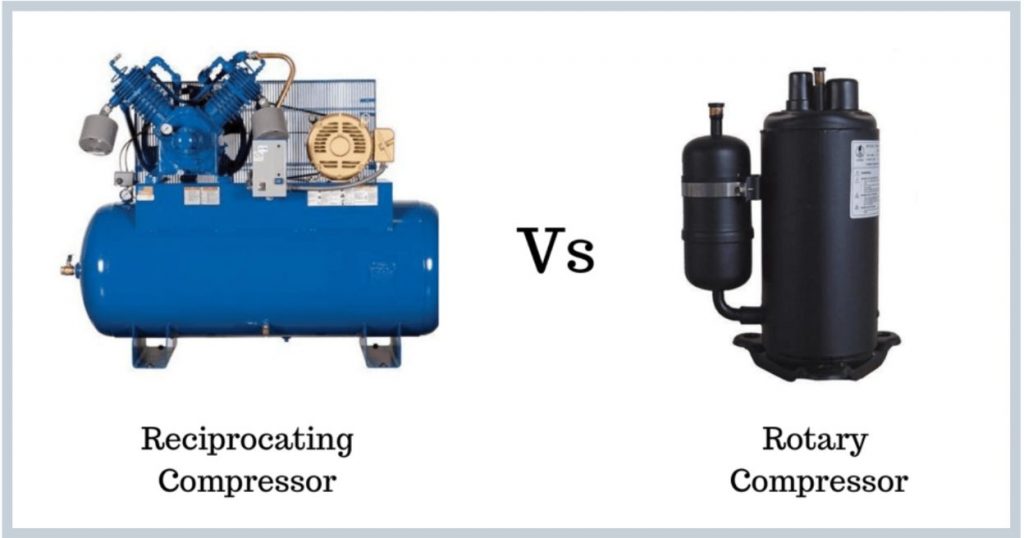

Reciprocating vs Rotary Compressor:

The primary function of a compressor is to offer a cooling effect! For AC units that are of smaller in capacity, i.e., less than 10KW are generally comes with a rotary compressor. In case of systems that work in between 10KW to 50KW, uses scroll compressors.

Hence, whenever you want to buy an AC, it is suggested to read the intimate details of the machine thoroughly. You need to know, especially about the type of compressor it includes. So that you can get more idea about how efficient or reliable that particular system will be going to be for your use case.

Generally, in the case of air conditioners available for our houses and offices, two main types of compressors are there, we can find in them. They are rotary and reciprocating. Now due to less clearance, the refrigerant gets high pressure inside them. A scroll is also a type of a rotary compressor.

Today inverter ACs have DC inverters that control the compressor speed and make them never shuts off completely. Thus, it results in less damage to the parts, overall quieter, and silent operation with no sudden fluctuations!

To summarize here, the reciprocating compressors are the same as that of an automobile engine. It consists of multiple cylinders that work together and includes a piston that moves to decrease the volume of the refrigerant. They are generally easy to maintain and more efficient. But a user needs to face noise and vibration issues.

In the case of rotary, it has a pair of two rotors explicitly designed to move opposite to each other. On the positive side, they are best to be used on AC systems for large scale applications and produce less vibration or noise. In terms of downsides, they are expensive than reciprocators. They can offer better performance and durability with continuous usage.

There is noticeably a bundle to know about this.

I consider you made some good points in features

Thanks!

Excellent post. I was checking continuously this blog and I’m inspired!

Very helpful information specifically the

ultimate section 🙂 I handle such information much. I was seeking this certain information for a

very lengthy time. Thank you and best of luck.

Thanks

Thanks!

Its like you learn my thoughts! You appear to grasp a lot about this, such as

you wrote the e book in it or something. I feel that you could do with

some p.c. to force the message house a little bit, but other than that, that is

magnificent blog. An excellent read. I will definitely be back.

Thanks!

Thanks! 🙂